Inventory cataloging and putaway choices for my sports card collection

I have been collecting sports cards since the mid 1980's (40+ years) and have amassed a pretty decent sized collection. I created Collectz to use data + machine learning to help me find arbitrage opportunities for collectibles market, helping me understand demand + pricing as both a buyer and seller.

The Challenge - How to store my cards?

It is really hard to sell things when:

- you don't know exactly what you have

- you can't find your items

- adding items is difficult

I want to be able to organize my inventory in a way that makes it easy to add, find, replenish and sell items.

Best Practices for Putaway

The putaway process in a warehouse is the initial placement of goods, which can have a direct impact on other warehouse processes, especially picking. A well-designed putaway process can help improve inventory accuracy, reduce picking times, and free up warehouse space.

There are several putaway methods that can be used in a warehouse, depending on the size of the warehouse, the type of goods being stored, and the volume of goods being received. Some of the most common putaway methods include:

Directed Putaway

This method is used when goods arrive at the warehouse but are not yet stored in a specific location. In this case, a Warehouse Management System (WMS) will use logic to determine where each item should be placed based on frequently ordered items, size, type, etc. This method is designed to ensure that goods are stored in the most efficient way possible while minimizing the time and effort needed to find and retrieve products. Often referred to as slotting.

Fixed-Location Putaway

This method requires items to be moved manually by staff and stored in pre-designated locations within the warehouse. This is usually done with an item’s size, weight, and usage rate in mind. This method is best used for items that are regularly reordered, as it allows warehouse staff to quickly and accurately locate the item when needed. Often these fixed locations are replenished from bulk locations.

Dynamic Putaway

With this method, each item is given a unique location within the warehouse based on its characteristics. The system will then assign items to these locations when they are received. This method is best used when products are not regularly reordered, as it eliminates the need to constantly move them from one location to another.

My Logistics Experience

Over the years, I have worked at companies each running multiple warehouse buildings (with 100's to 1000's of warehouse employees) and have seen how they organize their inventory:

|

Apex One - (Licensed Sports Apparel Manufacturer) Primary Method: Fixed-Location During my college days (1992-1994), I worked on the warehouse floor - receiving, putaway (driving cherry pickers is fun), picking and packing orders. |

|

Dell - (Computer Manufacturer) Primary Method: Directed During the dotcom boom + bust (2000-2005), I worked in the professional services division of Dell. Their world class logistics facilities in Austin, TX only carried inventory for 4 hours. |

|

Rent the Runway - (Clothing and Apparel Rental) Primary Method: Fixed-Location, then Dynamic From 2014-2020, I worked on software and data teams at Rent the Runway. Complex receiving + putaway challenges as part of the reverse logistics elements when customers would return their rentals. |

My Initial Approach

I had too many boxes in different sections of my warehouse (AKA my office in my house) with so many of my cards mixed up randomly. For the past 10+ years I kept buying cards online and at card shows and sometimes would list a handful at a time in auctions on eBay, sportlots or sportscollectors.net. I had a vague idea of what I had, but it was rarely easy to know where to find them.

Fixed-Loaction Putaway as a primary method

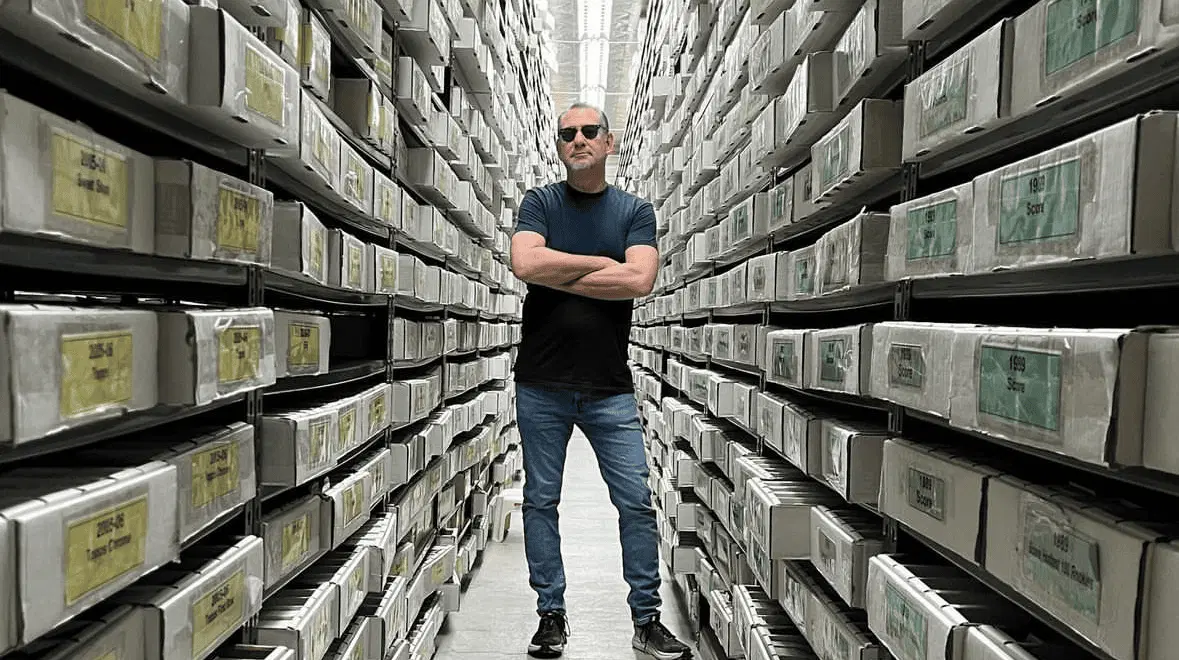

In the spring of 2023, I watched videos of how Burbank Cards sets up their warehouse with over 41 million cards - likely the world's largest sports card inventory by a single seller. Dave (the owner) described how they organize their inventory by sport, year, set and number in 5000 count monster boxes and put the boxes in specific areas on racks in their warehouse. It is a prototypical example of Fixed-Location Putaway described above.

An aisle at Burbank Cards warehouse with racks of card boxes on each side.

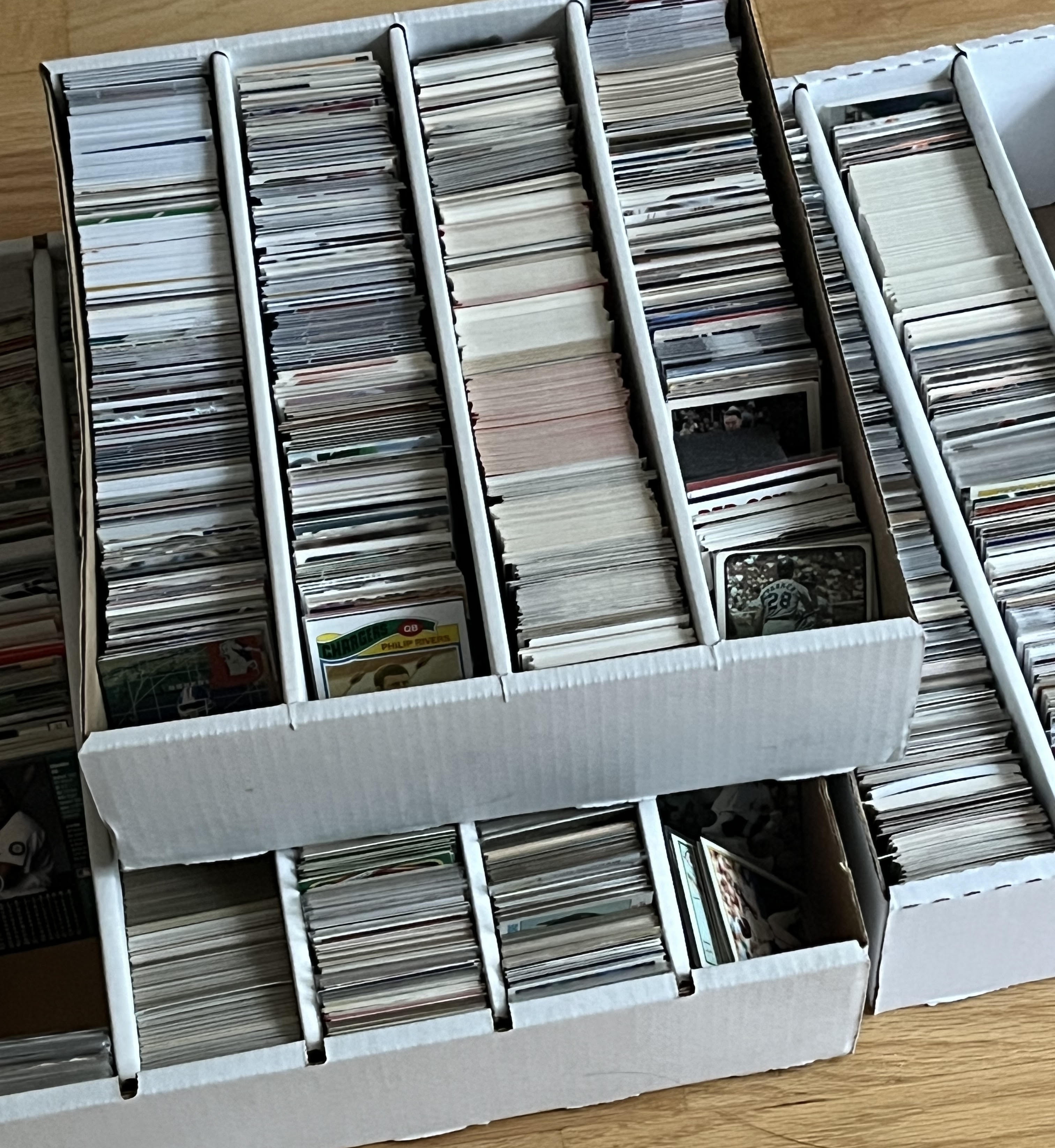

Since I have seen other card sellers organize their inventory this way and it worked for Burbank Cards at scale, I figured using Fixed-Location Putaway would be a good approach for my collection - even though my space is limited and my scale is considerably smaller. My office was engulfed in piles of cards as I spent about 2 months sorting my unsigned cards by sport, year, set and number.

A portion of my football card inventory sorted into monster boxes.

Inside each box, cards are divided by year and set, sorted by number.

The Results after 1 year

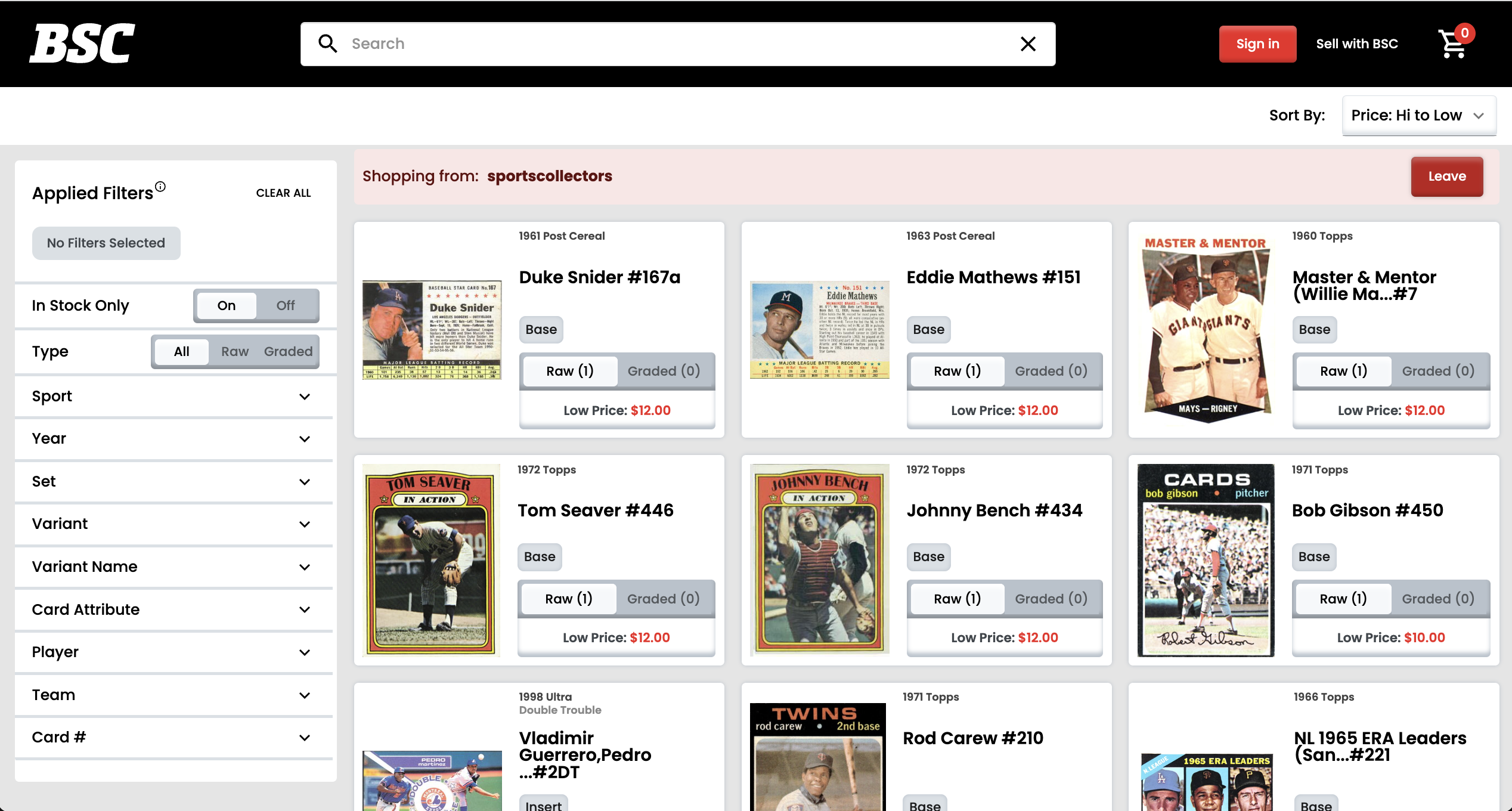

After I finished getting organized, I felt so much better about knowing I had a system in place. With some help from my kids, I listed over 60K unsigned cards on BuySportsCards (my seller name is sportscollectors):

You can check out my cards on BuySportsCards.com.

I am reasonably happy as I have been able to sell a bunch of cards on this platform that would have been very difficult before my improved organization:

- I average about 4 orders/week.

- I average about 10 minutes to pick and pack up an order. This feels long.

- Profit margins are consistently better now than before I was organized.

- Pre 1980's era seems to be my most popular cards that I sell (especially baseball).

- The biggest order was over 150 cards across 10 boxes, took over 45 minutes to fulfill.

Adding a lot more inventory is TOO HARD

I have recently purchased several larger bulk lots of cards. I now have about 15,000 more cards that I have not yet cataloged. I had been putting off adding them to my inventory as it is a lot of work to sort them into the right boxes. I would have to move so many cards around in boxes to make room. This will likely be more labor intensive than the original sorting last summer. YUCK!

Collection I bought this month that I need to catalog.

More Efficient Approach

While I am certainly happy with my organization and my sales, I could not bring myself to sort new items and then shuffling them around in a Fixed-Location scenario.

I think it is pretty obvious that I needed something else! Thankfully, I can learn from some of my experience and discussions with friends who are into solving logistics prolbems.

Case Study: Rent the Runway moved to Dynamic Putaway

When I joined Rent the Runway in 2014 and spent time in the warehouses, their Fixed-Location set up was challenging as the seasonality + trends of their business meant that they would have empty spaces on their racks at different times and have to move items around. There were regular concerns about running out of physical space in their warehouse as new inventory was acquired each season.

Rent the Runway's Fixed-Location set up, with items grouped by style.

In 2019, they moved to a Dynamic Putaway method where each unit could be put away to any location within the warehouse and each unit's location was tracked in their homegrown WMS. This method allowed them to store items in the most efficient way possible while minimizing the time and effort needed to find and retrieve products. This enables the ability to generate pick lists that consider the optimal physical proximity of items within warehouse.

Better Solution - Directed + Dynamic Putaway

Because I try to sell across a variety of marketplaces, I can leverage different putaway methods to accomodate my needs. Not all of my inventory is going to have the same demand and it doesn't always make sense to list each card individually for sale on a traditional ecommerce storefront or marketplace (like BuySportsCards).

When to use Directed Putaway

I suspect the majority of online and in person sellers use some form of Directed Putaway, where they regularly list a smaller portion of their inventory for sale and don't fully catalog their items. For me it makes sense for the following scenarios where I do not need to catalog them individually:

- I am selling many cards in a lot or in bulk.

- I take a picture of a group of cards and offer them individually on a message board or Facebook group. It is very common on Facebook to see a seller post a picture of 9 or 18 cards and offer each of them all at the same price.

When to use Dynamic Putaway

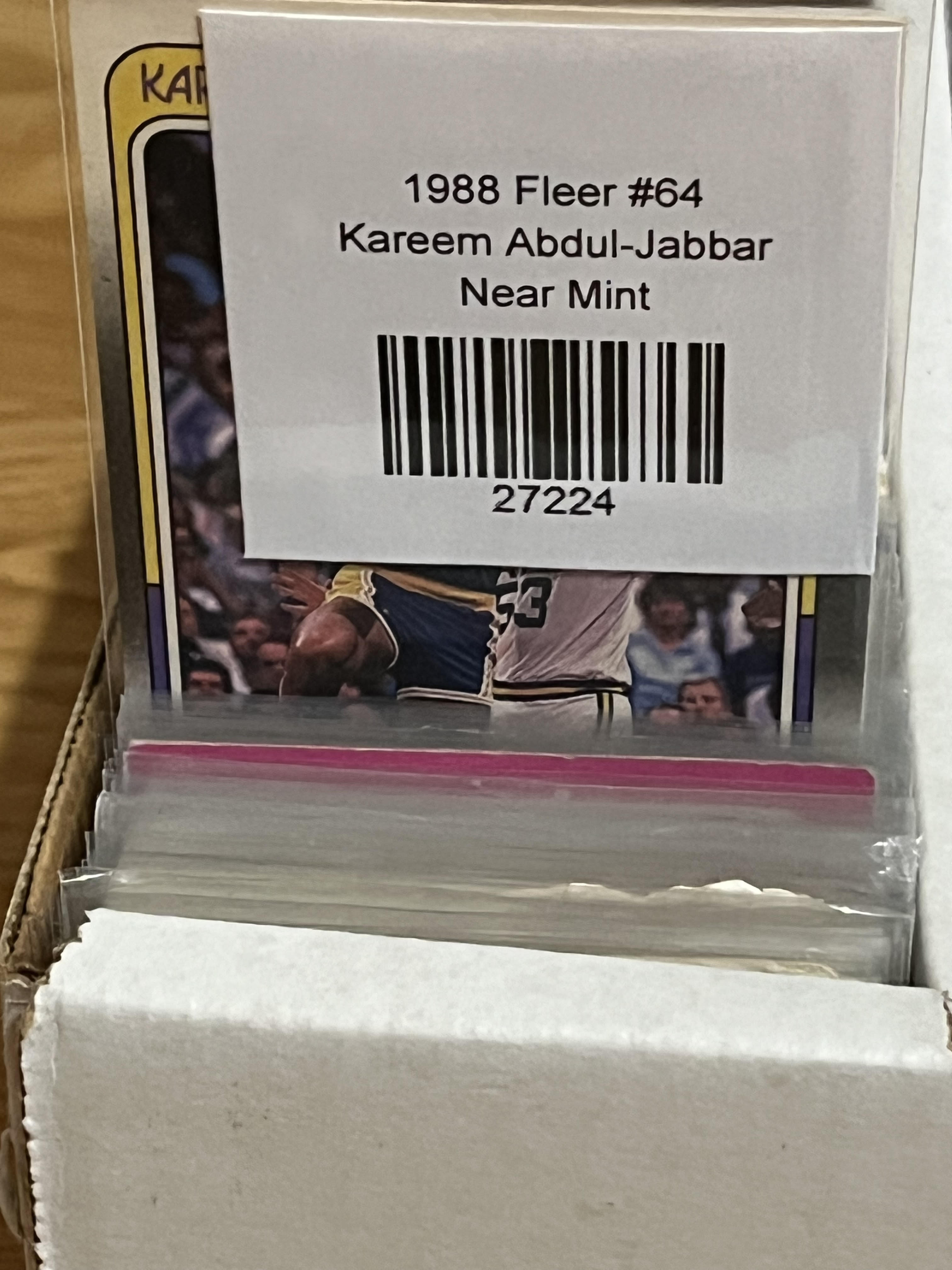

For the new inventory that I plan to catalog, I have switched to using Dynamic Putaway. The heavily automated process I have is pretty simple:

- I choose a card and associate it with its sku in Collectz (my WMS).

- I scan in the front and back of each card (optional).

- The system assigns a numbered barcode to each card.

- I attach the barcode to the card and put it in a box in numbered order.

Card with bar code being placed into Dynamic Inventory.

I can use my WMS to track the location of each item within my warehouse. This allows me to quickly add new items to my inventory without having to invest any effort in sorting. This also allows me to more easily find and retrieve items when needed, as the system tracks the location of each item within the warehouse.

Conclusions

It's really cool when things I help solve and learn from in my day jobs can be applied to my passion project. I am excited to see how this new approach will help me grow my collection and sales in the future.